In electrical engineering, the electrical machine is the most prominent part. As electrical engineers, we should be familiar with the basics of machines.

Here, I am trying to cover the basic concepts of electric motors and their types.

Basic of Electric Motor | Definition

Everyone knows the basic definition of an electric motor.

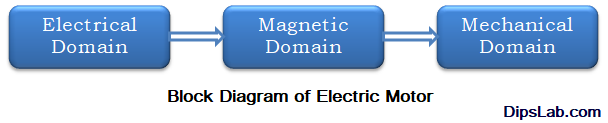

The simple definition of an electrical motor is to convert electrical energy into mechanical energy to perform moving or rotating tasks.

See here a simple diagram of the motor.

As per the working role, it is very beneficial and essential for moving machinery, vehicles, or other rotating objects.

Types of Electric Motors | Classifications

There are different types of electric motors. Its classification depends on specific parameters such as construction, working role, applications, operating principles, function, and many more.

Let’s study motors’ types,

1. Electric Motor

Based on the DC (Direct current) and AC (Alternating current) sources, the two types of electric motors are classified.

- DC Motor:

DC motor is working (or running) based on the DC source. It is mainly used where adjustable speed and torque control are needed.

DC motor is divided into three types such as DC series motor, DC shunt motor, and DC compound motor.

- AC (Alternating current) Motor:

AC motor has a power source from the AC source. AC source comes in both single-phase and three-phase variants.

It is classified into two types. One is the ‘Induction motor’ and another is the ‘Synchronous motor’. The hysteresis motor, reluctance motor, and permanent magnet motor are the types of ‘Synchronous motors.

For commercial and industrial applications, it is widely used to operate at a suitable speed that synchronizes with the frequency of the AC power supply.

Both have different specifications. Further learn here- Induction motor vs Synchronous motor

2. Stepper Motor

Stepper motors are mainly used for the open-loop control system. It requires a DC power supply. It has the best features that can easily control the speed, move with discrete steps, and precise position.

This motor is very beneficial for positional or motion control applications (for example- 3D printers, CNC machines, Textile machines, etc.) that produce high torque at low speed.

3. Servo Motor

Nearly, the servo motor is quite opposite to the stepper motor. It works for the closed-loop control system. The AC power supply is required as the power source for the servo motor.

This type of motor is widely used in position control, speed control, and torque control applications (for example- Nut tighten tools, Robotics, Shearing and forming machines, etc.).

More learn about the comparison of stepper motor and servo motor.

4. Hydraulic Motor

The main function of a hydraulic motor is to convert hydraulic pressure (or pressurized fluid) into mechanical motion (i.e. torque and angular displacement).

Hydraulic motors are used for many heavy machinery applications such as conveyors, excavators, military vehicles, roll mills, bulldozers, etc. Also, it plays a better role in heat transfer applications.

5. Pneumatic Motor

In other words, a pneumatic motor is also known as a ‘Compressed air engine’ or ‘Air motor’.

The feature of a Pneumatic motor is to convert the compressed air energy to mechanical motion in the form of linear motion or rotary motion.

It is found in hand-held tools, pulse tools, dental drills, tire changers, impact wrenches, and other pneumatic and industrial tools.

6. Brushless DC Motor

A brushless DC electric motor (BLDC) is also called as an ‘Electronically commutated motor’. It is type of a synchronous motor that requires a direct current (DC) power supply.

BLDC motor has more features and advantages as compared to the brushed motor such as high speed, low maintenance, high efficiency, instantaneous control of speed and torque, etc.

It is used in computer disk drives, printers, hand-held power tools, electric vehicles, drones, and more appliances.

7. Linear Motor

A linear motor is an electromagnetic device. It converts electrical energy into linear mechanical motion ( in the form of a straight line) instead of rotating motion.

This motor is found in MRI (Magnetic Resonance Imaging) machines, High-speed trains, conveyor systems, pick-and-place machines, and many more appliances that require linear movement.

8. Universal Motor

The universal motor can be used and operated on alternating current (AC) as well as direct current (DC) power sources.

It has some good features like as compact size, lightweight, versatile, capable of high-speed operations, etc. as compared to the other motors.

In power tools (for example- power drills, circular saws, and angle grinders), household appliances (for example- fans, vacuum cleaners, blenders, food processors, and mixers), and handheld appliances (for examples-hairdryers and sewing machines), it is widely used where versatility and compactness are essential.

9. Traction Motor

The main function of a traction motor is to produce motive force or power. The generated force helps to take action of driving or pushing forwards of vehicles as well as other moving applications.

The traction motor is used in different modes of transportation like as trams, elevators, roller coasters, conveyors, etc.

Especially, for electric train locomotives or EMU (electric multiple units) trains and some electric diesel or hybrid electric vehicles, this motor is played an integral role.

10. Gear Motor

The gear motor is an electric motor that is integrated with gearboxes. Both electric motors and gearboxes are used to achieve specific speed, torque, and output requirements for different applications.

Especially, this motor incorporates a gear reduction mechanism within the motor itself.

The gear motor is used in any field as industrial automation, home automotive systems, telecommunications, printers, vending machines, conveyor belts, etc.

11. Hollow Shaft Motor

The hollow shaft motor is also known as the ‘Hollow bore motor’ or ‘Hollow shaft gear motor’. It has a hollow core or empty shaft at its center.

The better function of this motor is to allow for various applications where objects are required to pass through the center of the motor while still being driven or controlled by the rotation of the motor.

This type of motor is used in applications where space-saving, controlled motion, and the passage of materials or components.

Other classifications are based on internal combustion engines as including Diesel engines, Gasoline engines, and Jet engines. Diesel engines are used in trucks, buses, and machinery. Gasoline engines are used in automobiles and smaller power equipment. Jet engines are used in aircraft.

These are the various types of electric motors. Considering all these motors, each motor has unique working roles, construction, principles, features, and advantages.

Also, the motors are very beneficial to particular applications and factors (like as power requirements, speed, torque, force, and control precision).

In modern industrial automation, core industries, and transportation systems, motors make crucial things. Without the motor, the system or device will not properly work.

In an upcoming article, I will describe each motor in detail. If you have any queries, you can hit comment below.

Read for more related articles:

- Stator vs Rotor

- Power vs Energy

- Motor vs Generator

- Active Power vs Reactive Power

- Alternator vs Oscillator

- Alternating Current Vs Direct Current

- Electrical Circuit Vs Magnetic Circuit

- Core Transformer vs Shell Transformer

Thanks for Reading!