If you look outside, you can see the electrical overhead system which is used for the transmission and distribution of electricity.

It has many electrical components such as a conductor, tower (electrical pole), insulator…

Here, the insulator is used for connecting many other electrical components.

Here, I am describing one of the most important overhead system components called the ‘Electrical Insulator’.

What is Electrical Insulator?

The electrical insulator is a device that provides the required insulation between the line conductor and the earth. Due to this insulation, leakage current can’t flow from the line conductor to the earth.

The basic definition of the insulator:

Insulator is a material or a device which restrics the flow of free electrons (or charge).

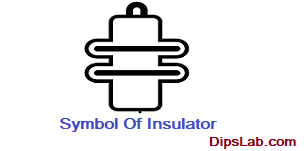

The symbolic representation of the insulator:

Moreover, the insulating material plays an important role in the making of various electrical and electronic circuits and overhead power systems.

Insulator has very high resistivity (offers very high resistance). Due to this high resistance, electrical current does not flow from one point to another.

Important Electrical Insulator Properties

Insulators have some specific properties that make them different from other electrical devices.

- The electrical insulator has a high resistivity.

- Insulator has good mechanical strength for the conductor load.

- It has good dielectric strength.

- It has a high relative permittivity of insulator material

- The material used in the insulator is waterproof or non-porous.

If you compare insulators and conductors, both have opposite properties.

Which is the Best Electrical Insulator Material?

Insulators are made up of different types of insulating materials like plastic, rubber, mica, wood, glass, etc.

In the electrical system, specific insulating materials are used like porcelain, glass, steatite, polymer, ceramic, and PVC.

- The porcelain material of the insulator is best in an electrical power system. It is commonly used in overhead transmission and distribution systems.

- Glass types of insulating material discs are also used in suspension or strain insulators.

Multiple insulator materials are easily available in the market.

Why are Electrical Insulators Important?

The insulator work as a Protector or Protective device. Because it provides high resistance.

Here are some important reasons to understand the importance of insulators.

- Insulator helps to protect from heat, noise, and electricity.

- The insulator is used to support the overhead conductor.

- It is commonly used to insulate the live parts of equipment or conductor from the earth.

- The live conductor is protected by wrapping the insulation.

- It helps to protect switchgear, transformer, and other systems in a substation.

Basically, an insulator protects devices from overload.

Insulator Types

Which type of Insulators are used in Power Systems?

In the transmission and distribution systems, six different types of insulators are used. These six types of insulators are selected on the bases of voltage rating.

Each insulator can have multiple insulating discs.

If one disc can sustain an 11kv voltage capacity and six discs can sustain a 66kv voltage.

Insulators are classified into six different major types.

- Pin Insulator

- Strain Insulator

- Shackle Insulator

- Suspension Insulator

- Post-Insulator

- Stay Insulator

Let’s dive into each one by one.

1. Pin Insulator

The pin types of insulators are mostly used in the distribution system.

Specification of Pin Insulator:

- Pin insulators can sustain up to 11kV voltage capacity.

- It is made up of material that has high mechanical strength.

- It can be connected with horizontal as well as vertical positions.

- This type of insulator is used in the high-voltage overhead distribution line.

- The pin insulator has a simple construction.

- It requires less maintenance as compared to other insulator types.

2. Suspension Insulator

The suspension insulator is called as a Disc Insulator. Mostly, suspension insulator is made of glass or porcelain insulating materials.

Especially, glass types of insulators used in lightweight conditions.

Specification of Suspension Insulator:

- The voltage operating capacity of the insulator is from 11 kV to 765 kV.

- It is mostly used in the overhead transmission system or line.

- It provides more flexibility to the overhead line.

- The multiple discs can be used based on voltage level (low to high).

- It is generally placed with a steel tower.

- The suspension insulator requires more height for supporting the multiple discs.

In a transmission line, why suspension insulator is better than others?

The suspension insulators are most beneficial than the other insulator. Because, if any of the discs are damaged by the suspension insulator, the remaining disc will operate. The damaged disc can be replaced, easily.

3. Strain Insulator

The strain insulator is similar to the suspension insulator type. Like a suspension insulator, a strain insulator can be used in the overhead transmission line.

But, it has slightly different specifications and working roles.

Specification of Strain Insulator:

- It is used in higher voltage conditions i.e. above 33 kV.

- Primarily, it is used in the bend or arm place of the transmission line.

4. Shackle Insulator

Shackle Insulator occurs in small size on the overhead distribution system.

Specification of Shackle Insulator:

- In the distribution line, the metallic strip is used to connect the shackle insulator.

- This insulator has a bearing capacity of up to 33 kV voltage.

- In the circular turn or bend position, a shackle insulator can work.

5. Post-Insulator

Post-insulators are commonly used in the substation or generating substation.

Specifications of Post Insulator:

- In a substation, it is suitable for different voltage levels (from higher to expected lower voltage).

- Always it is placed in a vertical position.

- It helps to protect switchgear, transformers, and other connecting devices.

- This type of insulator has strong mechanical strength.

6. Stay Insulator

The stay insulator is known as the Egg Insulator because it looks like an oval or rectangular shape.

Specification of Stay Insulator:

- Stay insulator is used only in the distribution line.

- It occurs in small sizes as compared to other insulators.

- It always places in between the line conductor and the earth.

- The insulator works as a protective device when a sudden fault condition or voltage change occurs in the line conductor.

| Insulator | Voltage Capacity | Power System |

| Pin Insulator | < 11 kV | Distribution System |

| Suspension Insulator | 11 kV to 765 kV | Transmission System |

| Strain Insulator | > 33 kV | Transmission System |

| Shackle Insulator | < 33 kV | Distribution System |

| Post-Insulator | > 11 kV (High) | Substation |

| Stay Insulator | < 11 kV | Distribution System |

This is all about different insulator types, uses, and their specification. If you have any point to discuss about insulators, write in the comment section.

Thanks for Reading!

Dear Dipali,

Your articles are Very knowledgeable, & useful for electrical engineer, electrical contractor, electrical students.

I appreciate to you.

Regards,

Umesh

Consultant(E&I)

Thank you very much, Sir.

I am very glad and motivate, if my knowledge can contribute to the learner.

Nice Article.

Thank you, Sir!

Very knowledgeable & useful Articals.

Thank you, Sir:)

Good information about insulators. All needed information at a place.

Thank you, Naveen!

Nice.

Thanks. Nazeer.

Good Information Dipali

Thanks, Nikita 🙂

Thanks, for sharing the important information.

Glad 🙂

Thanks for sharing.

My pleasure to share with DipsLab readers.

Very useful

Thanks, Sreenath for reaching out to my blog.

Thanks

Madam, your article is very useful and I think, many upcoming and newly Engineers will be helped to read this article. It would very nice if different types of insulators picture included with this. Thank you.

Thank you for finding it useful.

In this article, I have shared a video on ‘Different types of Insulators’ where mentioned each insulator picture.

Also, you can check here-

https://www.youtube.com/watch?v=8aMJVCRA87g