In this tutorial, I am describing one of the most important topics-

- What is an Electrical Transformer?

- Explanation of transformer’s construction and its main parts.

Also, I will add the functions of each part of the Transformer. So, it will make you understand easily.

Let’s dive into the basics of the transformer.

What is Electrical Transformer?

The basic definition of a transformer-

An electromagnetic device which is used to step up or step down the voltage level with respect to increasing or decreasing alternating current level at a constant frequency. This device called as an Electrical Transformer.

Sometimes, an electrical transformer is called an Electrostatic device. Because, it doesn’t consist of removing apart.

Here are listing some important points and function of transformer.

- The electrical connection does not occur in the transformer, only the magnetic connection occurred.

- Electrical transformer works on a principle of Faraday’s Laws of Electromagnetic induction.

- It requires and works only the alternating current (AC) source. And AC source helps to generate the magnetic flux in the electromagnetic field.

- It is a protective device by regulating (raising or lowering) voltage in an electrical power system.

- The main function transformer is to transform the power from one circuit to another circuit at a constant frequency.

- The transformer is more power-efficient and has very low transformer losses as compared to other electrical machines.

- The generating power in the transformer is always measured in KVA rating, not kW.

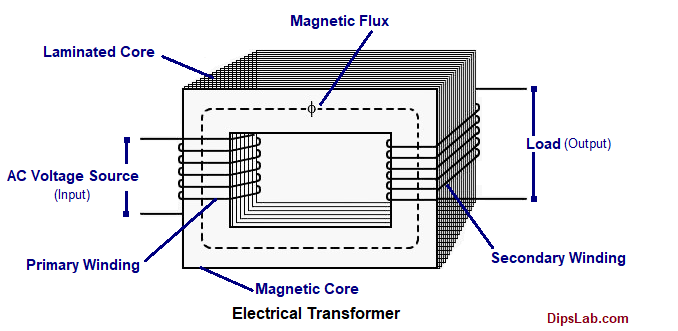

What is the construction of Transformer?

For the construction of the transformer, we require different types of components. Out of them, laminated iron core with copper windings and steel strips are the basic parts of the transformer.

Core laminations consist of thin metal strips of insulating materials. These laminations are insulated by a coat of varnishes or papers and wrap around the limb.

You can easily understand from given transformer diagram.

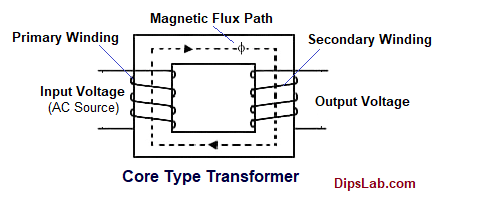

It consists of two types of windings such as primary winding and secondary winding.

These windings are separate and made by an electrical copper coil (number of turns). AC voltage source is provided to the primary winding and load is connected to the secondary winding.

We were already discussing, the transformer winding is not electrically connected to each other, but it is magnetically connected.

The main function of the core to support the winding and to provide a low reluctance path for flowing magnetic flux whose maybe a flowing useful flux.

Let’s study other essential components for the construction of transformer.

What are the main parts of transformer and its function?

Several parts of the transformer are given different specifications with the works as follow.

- Laminated iron core

- Transformer winding

- Insulating materials

- Tap changer

- Transformer tank

- Oil conservator tank

- Breather

- Buchholz relay

- Bushing

- Cooling tube and radiator

- Explosion vent or valve

Let’s study of transformer parts and functions one-by-one.

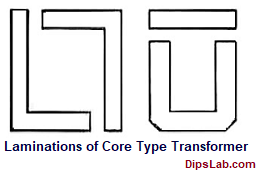

1. Laminated Iron Core

The transformer’s core is made up of iron or silicon steel or ferromagnetic materials.

The iron core made of thin metal strips and lamination insulated by a coat of varnishes or papers. Each metal strip has a thickness near about the o.5mm.

In the below figure, you can see the number of metal strips connected to each other with the lamination layer and form a single core.

Laminated Iron Core

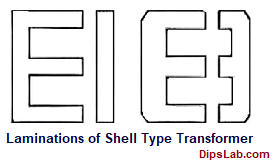

Basically, ‘L’ and ‘E’ shaped laminations are used in different types of transformers.

In the core type transformer, ‘L’ or ‘U’ shaped lamination is used.

And shell types transformer ‘E’ or ‘I’ shaped lamination is used.

This core lamination helps to reduce the eddy current loss and hysteresis loss.

The basic function of transformer core is-

- to provide a low reluctance path and

- to provide high permeability for the flux in the magnetic circuit.

2. Transformer Winding

The transformer winding is consists of several turns of the copper coil. It is wrapped around the limb or core with lamination.

The power transformer windings laminated by the insulation coating. Because, it prevents the short circuit condition.

What are the types of winding in transformer?

On the basis of supply, two types of winding are used.

- High voltage winding

- Low voltage winding

Simply based on core construction, there are two types of winding.

- Concentric types winding

- Sandwich types winding

I. Concentric types of winding:

Concentric types of windings are generally used in core types of transformer. It contains the only single path for mutual flux (Φ). And theses flowing fluxes are equally distributed on the side limbs of the core.

The single flux path is shown in the following figure.

Concentric types of winding consist of various kinds of winding like,

- Helical types winding

- Disc types winding

- Core types winding

In these core types of the transformer, windings are surrounded by the core. So, it requires a huge amount of copper coil and laminated materials.

II. Sandwich types of winding:

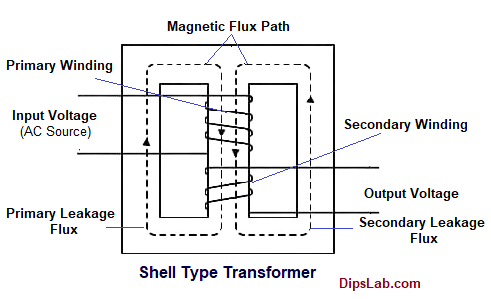

Sandwich types of winding are used in shell-type transformers. In a shell-type transformer, the primary and secondary winding is placed on the central limb.

This central limb carries two flux paths (mutual flux and leakage flux) in the magnetic circuit.

You can see the above diagram, in shell types of the transformer, the core surround by the winding.

Read more details: Core Type Transformer vs Shell Types Transformer

3. Insulating Material

In the transformer, insulating materials rely on their voltage rating. Different types of insulating materials are used in the transformer.

These insulating materials maybe a transformer oil, insulating paper, wood, the insulating glass material, tap changer insulating coil from grounding, etc.

4. Tap Changer

Tap changer is to regulate supply voltage or load. And it maintains both conditions (i.e. source or load) by changing the variable turns.

The tap changer is easily removed from the first turn and connects to the next turn ratio. Tap changers can occur on the primary side or secondary side.

Generally, a tap changer use in the high voltage winding side because it reduces load current.

Classification of Tap Changer –

It is classified into two following category,

- No-load tap changer

- On-load tap changer

5. Transformer Tank

The transformer tank is a cylindrically shaped tank. It is made of steel metal with a high thickness. Core, transformer windings, and oil is placed in the transformer tank.

Basically, mineral oil (i.e. Naphthenic mineral oil) or synthetic oil is used in transformer tank.

This oil provides insulation and cooling to the transformer winding.

6. Oil Conservator Tank

The oil conservator tank looks like a rectangular tank. It stores the extra oil and it is directly connected with the transformer tank.

The oil conservator tank is played an important role in the transformer.

The purpose of the conservator tank is to protect the expansion of oil in the main tank of the transformer. The oil is used in the transformer for two purposes-

- Insulation

- Cooling

When the oil level reduces due to losses or leakage, the conservator will be delivering oil to the transformer. Thus, It acts as reservoir oil.

7. Breather

The breather is connected with the conservator tank. It is a cylindrical vessel which is filled with blue color silica gel.

They have two purposes-

- to remove the moisture from the air,

- to have the capacity to absorb the moisture in a transformer.

It plays a role to act as the air filter and provide free moisturizing air to the conservator tank.

8. Buchholz Relay

Buchholz relay is a protective device that is oil and gas-operated the relay. It is connected to the main transformer tank and conservator tank.

When the internal fault occurs in the transformer due to leakage flux, insulation core, core connection, breakdown core, etc. by producing excess heat.

This excess heat decomposes oil in the transformer and gas bubbles formed. Gas bubbles flow in the upward direction to the conservator and collected in the relay.

Buchholz relay is a fault detected by the amount of nature of gas and oil level in a transformer.

During several fault conditions, an alarm is alert then this command send to the circuit breaker and isolates the transformer.

9. Bushing or Terminals

The bushing is an insulating device that is made up of porcelain materials. The terminal of the bushing is provided a path of the conductor to the transformer tank.

With the help of the terminal, the transformer gives and provides the supply to another system.

In the transformer, two types of the bushing are mostly used- high voltage (HV) bushing and low voltage (LV) bushing. It relies on voltage ratings may be high voltage or low voltage.

10. Cooling Tube and Radiator

The cooling tube is necessary for maintaining the temperature and circulating cooling oil in the transformer.

And the radiator is connected with the transformer tank. It is also made of a number of metal strips or pipes.

Both the cooling tube and the radiator provide the same function in a different way. When losses occur in the transformer, heat is produced. This heat absorbs by the cooling tube and radiator in the form of cooling systems.

It is divided into two types of cooling systems.

- Natural cooling system

- Forced cooling system

In the natural cooling system, a cooling tube and radiator are used. And In the forced cooling system, we can connect the extra air fan to the transformer.

11. Explosion Vent or Vlave

The explosion vent is located at the topmost position on the transformer. The conservator tank is directly connected to the explosion tank with the help of a pipe.

The main purpose to prevent damage transformer oil tank by expelling boiling oil during an internal fault. And it is necessary to remove heated oil (in the form of gas) from the transformer.

This explosion tank use only for emergency purposes. It mostly works when a breather and Buchholz relay will not doing work properly.

These eleven main important parts of transformers are covered with the help of the tutorial.

If you are interested more about learning practically and building projects, here is the listing of the topmost challenging ideas for the Electrical Engineering Project based on Transformer.

Related read the following article:

- Different types of transformer

- Electrical circuit vs Magnetic circuit

- Single-phase vs Three-phase AC systems

- Electric Fuse vs Circuit Breaker

- Overhead system vs Underground system

- Distribustion system vs Transmission system

- AC transmission vs DC transmission

Ready for online test:

If you are ready to give the online quiz, you can directly join the Electrical Transformer Quiz.

Let me know if you have any queries, you can share in the comment section.

Thanks for Reading!

Your Blog is nice, I am talking about organisation of blog, I will go through content later.

Thank you so much!

Thank you!

Good and basic information in this blog. I like it.

Thanks 🙂

how to decrease voltage drop of transformer.

which type of lamination use for core assembly.(best material)

which type of coating used on lamination

– By using the winding

Provide the high resistivity and low permeability materials

By using the tap changer

– Silicon steel, Amorphous metal, Ferrite ceramic.

Mostly the Silicon steel provides the high electrical resistivity.

– The lamination which depends on the construction types of the transformer.

Lamination Maybe ‘E-I’,’E-E’,’L-L’,’U-I’ Types.

E-I core laminated transformer construction is mostly used in transformers.

Thank you very much .It is very useful in my life

You are most welcome, Jayesh!

Thank you very much

beautifully Explained

Thanks, Noniemmanuel!

Very well explanation.

Thank you, Benjamin Tettey!

Thanks you Dipali

And you have DC and AC Motor material. Please send link on my mail .

Right now, I don’t have specific material about this topic. Taking note of it. If I curate any tutorial, will update here.

Thanks, Pradhuman!

Very informative, thanks for sharing the knowledge.

Most Welcome,Robinson!

you have given very good information about basic things of Transformer. thank u very much

You’re most welcome, V.Vijender.

I’m willing to tell you that I appreciated your article, it’s useful for me, and help me have a good sense.

Thank you very much, Paul Robinson.

What type of material is used to manufacture the transformer tank, radiator?

The transformer tank and radiator both construct by the steel material.

You have mastered it very well master, quite interesting. can I get it in pdf format?

Sorry Sifiso, I don’t have stuffs in the PDF format.

Thanks for sharing the valuable information. It very much was useful to me.

You are most welcome, Mohan.

Hey Dipali, I have seen your tutorial. I want to suggest to you one thing your theoretical concept is remarkable.

But if you provide video tutorials as well then it’s very easy to understand (especially in the case of PLC languages and MATLAB).Great work.

Thank you very much, Savan for your suggestion.

I have already planned to start the YOUTube channel for sharing more videos. Soon, I will come in new year 2020.

Thanks for sharing the valuable information.

Respect from Pakistan.

You are most welcome!

Thanks so much.

You’re most welcome 🙂

Thank you so much.

You are most welcome, Milton.

Thanks

You are welcome, Sumit.

Firstly, I would like to say superb blog! Really, you’re doing a great job.

Thanks, Amira 🙂

Hey, I have some questions regarding the magnetic flux in the shell type transformer, what is its main function and primary and secondary.

Thank you

Megri

Thanks for sharing the best and useful information on transformer. You made a good site and giving us such great and useful information.

Thanks, Aradhana for reaching out to my blog.