AC motors are a goldmine for machines and devices that require mechanical power and it’s one of the oldest motors inventions introduced in 1888 by Nikola Tesla, that we still rely on nowadays.

But what exactly are AC motors, how are they built, is there a difference in the newer versions, and how do they operate? These are just some of the questions we’ll be answering in the article below, so keep on reading!

What is an AC Motor? and How does it work?

An AC motor is a type of motor that is powered by an alternating current and it uses it to turn it into mechanical power.

It works very simply as it only consists of a couple of components which even improves its lifespan.

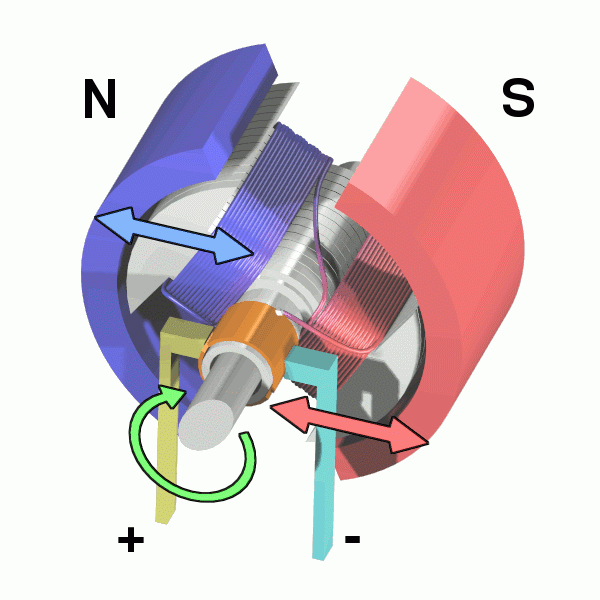

There is an outside stator and coils on the inside which get alternating current. The magnetic field is produced where the inside rotor then produces a second magnetic field.

This is how the whole AC motor functions and with the help of two magnetic fields, it has the ability to output mechanical power that can be used for various purposes.

However, it’s also important to note that there are 3 types of AC motors, including an induction motor, synchronous motor, and single-phase motor.

Each one of these operates a bit differently yet provides the same output, the ability to produce mechanical power from alternating current.

Components of an AC Motor

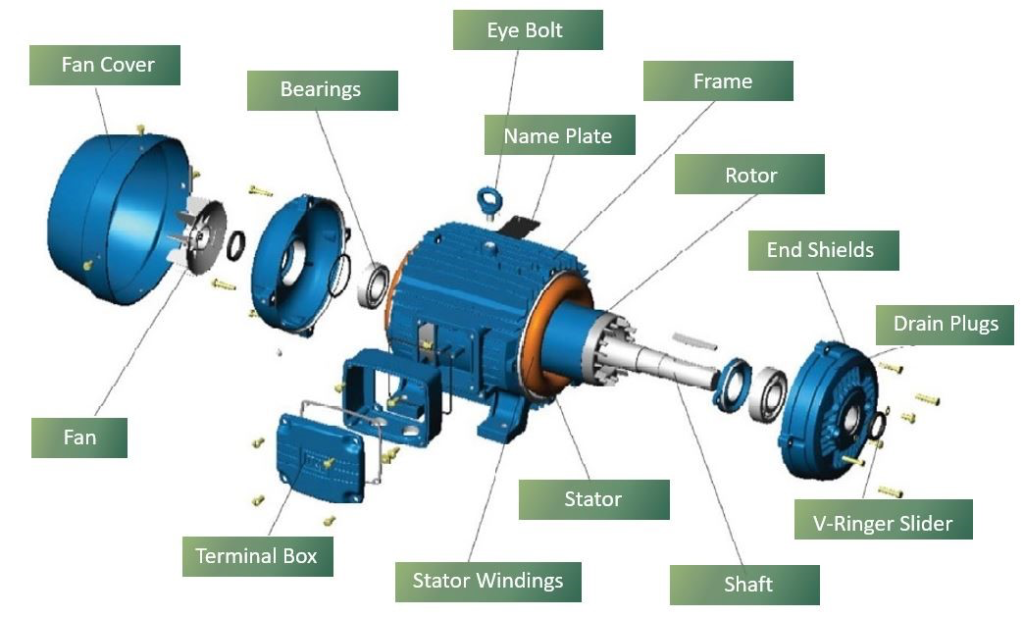

Two of the main parts of an AC motor include the rotor and stator. The easiest way to explain the stator is to think of it as the outer shell of the AC motor. That’s exactly what a stator is while the rotor is placed on the inside of the stator.

The stator also comes with additional components such as the windings which are helpful in transforming the incoming alternating current into a magnetic field.

This magnetic field magnetizes the rotor that’s placed on the inside of the stator. Since the rotor gets magnetized in the opposite polarity, as it repels, it rotates and that’s how mechanical power is produced out of the alternating current.

There are also additional components you can find in the AC motor such as bearings, cooling fan, and end bracket, that help support the rotation and the stability of an AC motor.

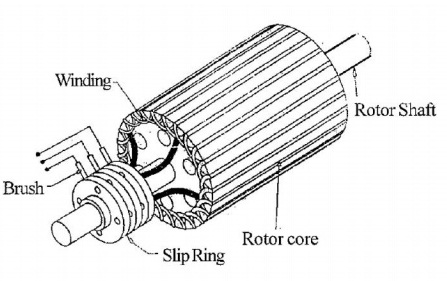

However, sometimes you might even come across a slip ring in the AC motor, and in the next section, you can learn why they are being used in some AC motors.

What is the role of a Slip Ring in the AC Motor?

Slip rings are tiny devices that help eliminate wire winding, reduce hanging wires around the joints, transmit power, signal, data, and more.

But how do they fit in the AC motor and what is their role, you might wonder?

Slip rings are very versatile devices and besides all the benefits they provide, they can also be used to add resistance to the rotor.

They’re even used on wind turbines as a way to prevent blades from spinning faster than they’re allowed to in order to eliminate any potential damage.

In the case of an AC motor, slip rings are sometimes used as a way to add resistance to help provide a smooth start of the motor under heavy load. The torque from alternating current will help bring the motor up to the speed and yet a slow and smooth start which is much needed in heavy machinery.

Therefore, companies such as Moflon produce a wide range of slip ring types that will fit almost any type of purpose and need. On top of that, Moflon can also produce custom slip ring solutions upon request so they can really fit any type of motor or machine.

Benefits and Advantages of AC Motors

We’ve previously just mentioned the AC motors’ ability to provide a slow and smooth start which is actually its one of the biggest strengths.

It provides a lower startup power on demand whenever it’s needed. This also adds additional advantages such as better control of current level start, and better acceleration.

Since AC motors are very simply built yet provide an incredible functionality that is still used to this day, they’re also very customizable so with proper knowledge, it’s easy to configure an AC motor to adapt it to requirements.

With a simple design and high-quality materials used to produce the AC motors, they provide long durability and great lifespan. Therefore, a single AC motor can last up to 15 years, and with proper maintenance, it can last much longer than that.

How are AC Motors Used in Real Examples?

Since AC motors are really good at generating mechanical power using the alternating current, they’re very versatile and with the ability to adjust the speed and provide a slow start yet endure a heavy load, they’re used in almost every industry and niche.

Therefore, some of the most common real examples of AC motors in use include pumps, ovens, off-road vehicles and equipment, gardening equipment, water heaters, and more.

AC motors can also be found in many appliances we use on a daily basis, as well as tools and equipment. These include computers, fans, air conditioners, transportation equipment, hydraulic pumps, compressors, and various appliances almost everyone owns in their household.

Conclusion

AC motor is a very simple invention that is really efficient and is still being used to this day. With only a couple of components and a wise design, it has the ability to turn alternating current to mechanical power with the help of magnetic fields.

While many know AC motors, very few know that there are more than 1 type of them, but one thing almost no one knows is that slip rings are being used to add resistance to the motor.

Have you ever come across an AC motor and do you know at least one appliance we use on a daily basis that utilizes an AC motor?