Nowadays, multiple companies are manufacturing and designing the programmable logic controller (PLC) software as well as hardware devices.

In an earlier article, we have seen topmost PLC brands and their useful software. Here, we are going to study PLC rack of the hardware devices which are mostly used in the industrial environment.

Generally, Fixed PLC and Modular PLC types of PLC are constructed. But, modular PLC is mostly used in the industrial environment.

Sometimes, modular PLC is known as Rack-mounted PLC because, both are having the same functions.

Let’s starts from the basics of rack and chassis of PLC.

What is PLC Rack?

PLC rack and chassis are mostly used in the Modular PLC or Rack Mounted PLC hardware.

Rack and chassis acts as a backbone of the PLC hardware system. It is helpful for assembling the modular PLC hardware modules.

Definition of PLC Rack:

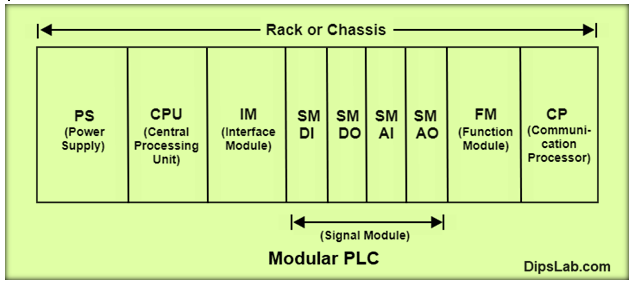

PLC rack or chassis is a hardware assembly that plugs communicating modules together (like input, output, CPU, power supply, communication, and additional function modules) in a single frame.

If you look at the below PLC designing structure, it looks more like a rack or chassis.

From the above diagram, you can see the multiple input or output modules that are plugged together in the same rack or chassis of modular PLC.

In the PLC rack, the power supply module provides the required level of the regulated power to the different input-output modules through the backplane bus system.

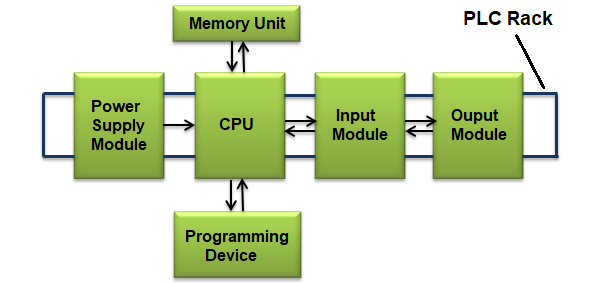

Rack Mounted or Modular PLC Block Diagram

There is a standard card where all the modules gets deployed to communicate through the rack.

With the help of rack and chassis, modules can be easily communicated to the other connected modules in the PLC system.

What are the types of Rack used in Modular PLC?

The modular PLC rack provides power and interconnectivity between multiple connected modules through the backplane.

Based on the backplane, rack are classified into different parts.

- Active Backplane

- Passive Backplane

1. Active Backplane

Active backplane consists of multiple slots and additional circuitry. It can easily control all communication between the slots.

Active backplane is mostly used in the Siemens (S7-400) PLC. Siemens (S7-400) PLC module can be placed into three different types of the rack.

- Central Rack (CR)

- Universal Rack (UR)

- Expansion Rack (ER)

These three main types of PLC rack are used in the modular PLC or Rack mounted PLC.

2. Passive Backplane

Passive backplane consists of only slots. This is no additional circuit. It is mostly used in the Siemens (S7-300) PLC.

What are the difference between Rack and Chassis of PLC?

PLC Rack and chassis has little difference. Otherwise, both are doing the same work.

Let’s see the main difference between the rack and chassis of PLC.

- PLC Rack:

The rack of PLC is a hardware device that holds together communicating modules in a single frame.

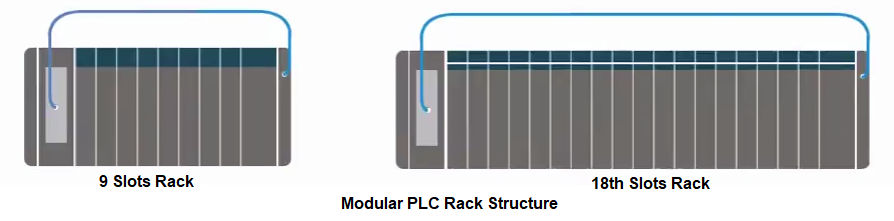

Rack is cabinet for placing the modules. It comes in a different sizes like 9 slots,18 slots, etc.

- PLC Chassis:

The chassis of PLC is a piece of hardware which has multiple slots for inserting the different or additional modules.

In the PLC system, there are different slots for chassis available. If the user wants additional chassis, we can connect them by using chassis interconnecting cables.

What is the Purpose of Rack or Chassis in PLC?

PLC rack and chassis has multiple functions to use.

- Rack or chassis distributes power in the PLC.

- It provides interconnectivity between connecting I/O PLC modules.

- In rack-mounted PLC, we can easily modify or expand input and output modules.

- It acts as a communication link between communicating modules.

- In any fault condition, we can easily remove and replace the individual module through PLC rack or chassis.

Hope you understand the difference between the rack and chassis of plc with the help of a circuit diagram of the rack-mounted PLC systems.

Interested to learn about software-based PLC programming? I have a curated tutorial on ‘[Step-by-Step] How to Learn PLC Programming at Home for Free?‘.

If you have any quires, you can freely ask with me by commenting below. If you find this tutorial helpful, kindly share it.

Ready for Test:

If you are ready for online test, click on is a PLC Automation Quiz.

Happy PLC Learning!

Please send advantage and disadvantages between RACK Mounted PLC and RAIL Mounted PLC.

Sure, Ashish. I noted this topic. Soon, I will try to share.

And you can share your query on our “Learn PLC SCADA Automation” group. Hopefully, group members will help you.

Dear ma’am,

Can you please explain the whole Control Pannel, with images of components and its working?

Thanks, Rajnish for suggesting. Sure, I will try to cover all these components with their specifications.