Hello Friends,

Stepper motor and servo motor are used for positional or motion control applications. In this article, we will see what is the difference between stepper motor and servo motor.

Table of Contents

Difference between Stepper Motor and Servo Motor

Explanation here,

1. Feedback System

Stepper motor is an open-loop system:

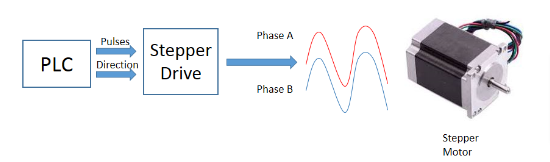

Open loop system of stepper motor of block diagram

Stepper Motor is an open-loop system that means it has no inbuilt encoder feedback from the motor to drive.

Programmable logic controller (PLC) generates PWM/PTO pulses and commands to stepper drive along with direction signal then stepper drive gives the supply to motor and motor starts rotating on steps.

Based on your number of pulses motor turns in steps. The motor does not give any feedback to the stepper drive.

Servo motor is closed loop system:

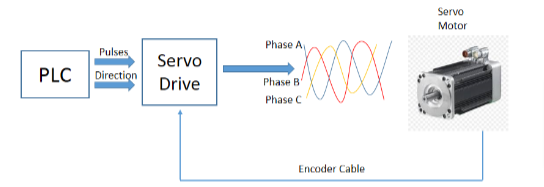

Closed loop system of servo motor of block diagram

Servo Motor has an inbuilt encoder and it gives current position feedback to the servo drive that’s why it’s a closed-loop system.

PLC generates PWM/PTO pulses and commands to servo drive along with direction signal then servo drive gives the supply to motor and motor starts rotating.

Motor gives running feedback to servo drive with the encoder cable and we can take this feedback in PLC through control cables.

Read more: Open-loop control system vs closed-loop control system

2. Speed and Torque

Speed and torque of stepper motor:

- Stepper motor has less speed than servo motor, the normal stepper motor has a maximum speed of 1500 RPM.

- As Motor speed increases motor torque reduces.

- It gives excellent torque in low-speed applications.

- Stepper Motor is not useful in the torque control applications.

Speed and torque of servo motor:

- Servo motor has a higher speed than a stepper motor, however, in the market, you will get different speed drive up to 5000 RPM.

- We get high torque at a higher speed.

- It gives excellent torque in high-speed applications.

- Servo Motor can be used in the torque control applications. (Ex. Nut tighten tool)

3. Electric Current

Current in Stepper Motor:

- DC Current is used to energize the stepper motor magnetic coil.

- Torque can be increased by increasing current.

- It consumes less power.

Current in Servo motor:

- Three Phase AC Current is used to energize the servo motor magnetic coil.

- Torque can be increased by increasing current.

- It consumes more power than a stepper motor.

4. Cost difference of stepper and servo motors

Servo motor and servo drive are more expensive than stepper motor and stepper drive. So for low budget application stepper motor is more preferable.

5. How to select motor for applications?

Select the stepper motor, if your requirement as per below,

- Your application should not require position feedback.

- For low-speed applications.

- You can use stepper motor only in position control applications.

- For simple machine applications.

- If your application is for holding torque.

Select the servo motor, if your requirement as per below,

- If you want position feedback.

- For high-speed applications.

- Speed control applications.

- Torque control applications.

- For complex machinery systems.

- For more precise and fast equipment.

6. Industrial examples of stepper and servo motors

Examples of stepper motor applications:

What is a stepper motor used for?

- Ball screw movement (spray painting or paper cutting machines)

- Precise up/down movement (welding machine)

- 3D printers

- Small robots

- Textile machines

- Medical equipments

For the above applications, you should consider the stepper motor as your first preference.

Examples of servo motor applications:

What is a servo motor used for?

- Robots

- Packaging machinery

- Camera auto-focus

- CNC machines

- Cutting machines

- Shearing and forming machines

- Proportional valve control

- Printing machinery

Finally, let’s see the summary of the differences between the servo motor and stepper motor in the tabular form.

Stepper Motor vs Servo Motor [in Tabular Form]

| # | Specifications | Stepper Motor | Servo Motor |

| 01 | System function | Open-loop system (no position feedback or encoder) | Closed-loop system (position feedback or encoder present) |

| 02 | What is the cost of stepper & servo motors? | Cost-effective | Very expensive |

| 03 | How fast can stepper & servo motors turn? | Low Speed (1500 RPM maximum) | High Speed (5000 RPM maximum) |

| 04 | Torque/ speed control odf | No torque-control or speed-control mode | torque-control or speed-control mode |

| 05 | Are stepper & servo motors AC or DC? | DC current use | AC current use |

| 06 | Torque of stepper & servo motor | High torque in low speed | High torque in high speed |

| 07 | Requirement | No tuning required | tuning required |

| 08 | Consuming power | Consumes less power | Consumes more power |

| 09 | Function | Simple and easier for commissioning | Complex for commissioning |

| 10 | Size | Maximum 750W motor size available | 50W to 15KW motor size available |

In the tabular form, I have described most of the topics related to the stepper motor and servo motor. Also, covered the advantages and disadvantages of using a stepper motor over a servo motor.

If you have any queries regarding stepper motor vs servo motor comparison, you can ask in the comment section.

Read some related differences:

- Stator vs Rotor of motor

- Active power vs Reactive power

- Analog signal vs Digital signal

- Squirrel Cage IM vs Slip Ring IM

- Synchronous motor vs Induction motor

Thanks for reading!

Many factors come in pictures while selecting stepper or servo….

1. Application, 2. Cost, 3. speed-torque curve, again as per application.

Great article. Thanks for sharing the useful information. People need to know the difference between the servo motor and the stepper motor. It will save them save a lot of time in selecting between the motors.

AC servo system is superior to stepper motor in many performance aspects, but the price ratio is different. Thank you for your sharing.

Well formatted article..

A stepper motor can be used with an encoder in a closed loop system. But that removes some of the cost advantage of an inexpensive stepper system

Also I believe you mean Tabular format not Tubular Format